MI8500

The MI8500 digital eddy current inspection and sorting system utilizes an advanced  technique called Magnetic Imagery. Magnetic Imagery is an advanced digital eddy current technique that provides the most complete on-the-fly metallurgical inspection Magnetic Image available on the market today.

technique called Magnetic Imagery. Magnetic Imagery is an advanced digital eddy current technique that provides the most complete on-the-fly metallurgical inspection Magnetic Image available on the market today.

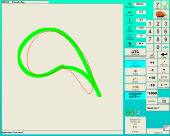

The instrument develops a magnetic image of each part as it passes through the eddy current coil to create the part’s signature. This full signature provides the opportunity to detect the most critical metallurgical defects such as cracks, material mixes, conductive plating’s, and hardness by a visual deviation in the magnetic display. The percentage of deviation is displayed and acceptable  limits can be quickly defined using the touch screen programming capabilities.

limits can be quickly defined using the touch screen programming capabilities.

The MI8500 machine inspects for: heat treatment (hardness), case depth, material mixes, wire seams and induction hardening. In addition to the metallurgical inspections, the MI8500 can sort for: mixed parts, missing and short threads, missing part features, part length and gross part damage.

Upcoming Events

October 25 - 27, 2016

National Industrial Fastener Expo

Sands Expo & Convention Center

Booth 737

Las Vegas, Nevada